The Art of Moulding

At Hi-Tech Polymer Products, we work with complex parts and materials on a daily basis.

We work hand-in-hand with various OEM’s across the industry in developing new and existing designs, providing them with prototypes, materials and design recommendations that improve upon both ergonomic and economic factors.

We also develop custom plastic mouldings for improved mechanical properties, flammability, outdoor exposure, chemical resistance, optical appearance standards and secondary operations.

Injection moulding

Reverse Engineering

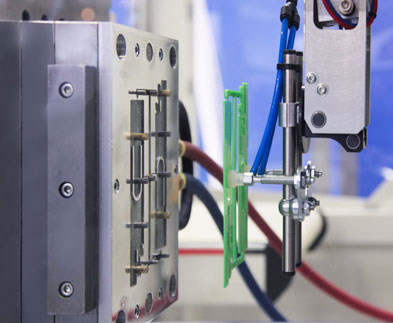

Insert moulding

Screen Printing

Over Moulding

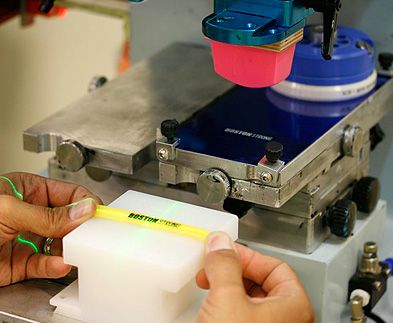

Pad Printing

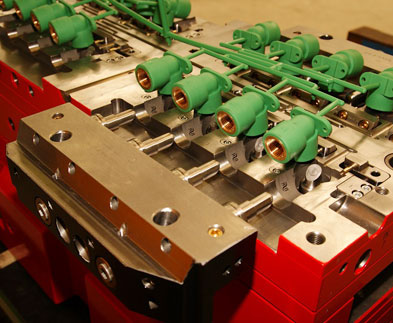

Hi-Tech Polymer Products carries out injection moulding for a wide range of thermoplastics. Our plant is spread over an area of 15,000 sq. ft. which includes a moulding shop, a tool room and a QA lab.

The moulding shop is equipped with 18 injection moulding machines, ranging from 35 T to 260 T. We use the latest servo and hydraulic micro-processor based machines, from Milacron, Kawaguchi, Nissei and Haitian.

The moulding shop is equipped with 18 injection moulding machines, ranging from 35 T to 260 T. We use the latest servo and hydraulic micro-processor based machines, from Milacron, Kawaguchi, Nissei and Haitian.

We also have an in-house tool room for prototyping, mould development, repair and maintenance activities. We can handle projects for prototyping and single cavity all the way upto high volume, multi-cavity injection moulds.

We have a fully equipped Quality Control and Assurance Laboratory for carrying out

inspection of incoming materials, child parts, in-process parts and finished goods.

Commercial Explosive Industry

Having worked with the explosive and mining industry since 1997, we have an in depth understanding and expertise in the technologies involved, giving us an edge in designing and development of plastic components, accessories and connectors to meet specific

requirements.

We have time tested knowledge on the raw materials to be used to eliminate the failures experienced in the field.

Automotive Industry

We partner with OEMs to develop high-precision plastic components meeting stringent dimensional standards for fool-proof assembly.

We mould engineering plastics, both filled and unfilled, like PA, PBT, ABS and PC.

We also ensure strict quality control at all stages of manufacturing, and are able to provide all the necessary documentation meeting the global IATF standards.

Hand Tool Industry

The hand tools industry range includes components and assemblies for measuring tapes, cases for hand tools and screw drivers as well as plastic moulded handles and grips.

Fit and finish are a vital part in these end-user products, which need to be manufactured at competitive rates to succeed in the market. We provide seamless fitting and high quality accessories, using multi-cavity tools to keep the production costs low.

CONTACT

+91-161-5036386, 9740579969

chhabraajit@hitechpolymer.com

business@hitechpolymer.com

B-XXIX/92/1-C, Oswal Agro Mill Complex, GT Road, Ludhiana-141003. INDIA

2020 – HI-TECH POLYMER PRODUCTS | Powered by : POINT INTERNET SERVICES